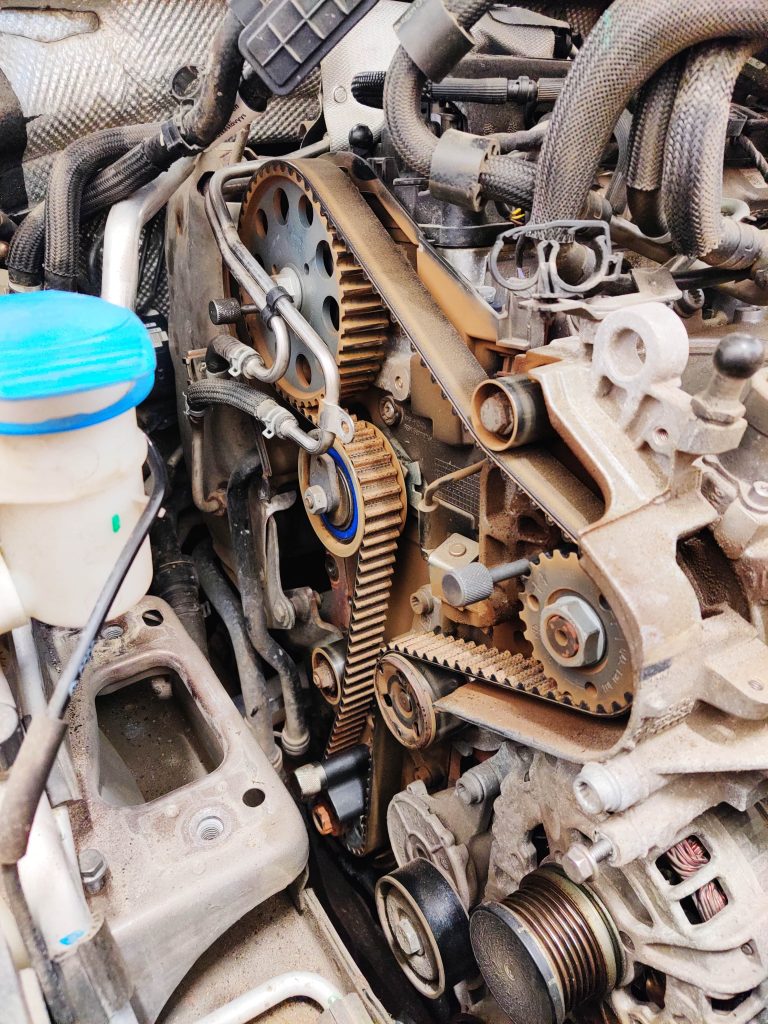

A timing belt, also called a cambelt, ensures that everything in your engine runs efficiently and effectively at all times, keeping you safe at all times.

As a result, timing belt replacement is a crucial maintenance job! If you enjoy cars, you should understand how a timing belt functions, how to recognise a defective belt, and how to repair it.

How Does It Work?

The timing belt’s duty is to balance the rotation of the crankshaft and camshaft of an automobile. Only when both are in harmony will your vehicle’s pistons and valves function properly. That is why, whether your automobile is brand new or several years old, you must have a working timing belt.

When Should You Replace Your Timing Belt?

It’s critical to change your timing belt just at mileage intervals recommended by your vehicle’s manufacturer.

The majority of auto makers recommend a replacement period of 100,000 to 160,000 kilometres. This implies the belt needs to be replaced every 100,000 kilometres, then every 200,000 kilometres, and so on.

Signs that your timing belt needs replacement:

- Your engine won’t start or is difficult to start

- Your engine makes a ticking or clicking noise.

- Misfiring engines

- Excessive emissions from your tailpipe

Configurations of timing belt:

These might include-

- Office equipment

- Electronic data processing equipment (EDP)

- Textile machinery

- Wood processing equipment

- Tools for machines

- Compressors

- Printing machinery

- Pumps with hydraulic gears

- Machines for construction

Timing belt materials

-

Rubber in timing belts

Rubber timing belts are the industry standard, with a wide range of applications and situations. A rubber timing belt was used on most internal combustion engine cambelts, such as those seen on the majority of automobiles (and definitely those built more than a decade ago).

-

Polyurethane timing belts

As a way of transmitting power, polyurethane timing belts provide a long-lasting and highly energy-efficient option for a diverse range of products in a number of sectors and industries. They have more suppleness than rubber and come in a variety of temperature and fuel resistance ratings.

-

Fabric timing belts

Fabric timing belts are favoured in higher resolutions and applications where extremely strong acceleration forces are required, as well as the transfer of high torque at low speeds.

Timing belt applications

Conveying belts – Timing belts on conveying systems are commonly toothed or ridged, allowing for accurate and responsive belt movement control and traction when used in conjunction with a toothed conveyor pulley.

Power transmission belts– Insofar as they transfer power from one section of a machine to another by the rotating motion of one or more components, all timing belts are fundamentally power transmission belts.

Linear positioning belts– Linear positioning belts are used in applications where precise movement and placement of components or parts are required. Polyurethane timing belts, as opposed to more traditional neoprene-type cambelts, are generally used in this type of setting since they have less elasticity.

Timing Belt Uses

We all know how vital a cambelt is in internal combustion engines, but what precisely does a timing belt perform, and how do other types of timing belts serve comparable functions in a number of other mechanisms and processes? The camshafts via the crankshaft as the different sections rotate at a regular ratio of speeds in an engine. Thus, these components work together to open and close the input and exhaust valves of an engine.

Summary

So far, we’ve spoken about what a timing belt is, how it functions, and the signs and symptoms of a faulty timing belt. You should be able to recognise the symptoms of a worn-out belt by now, and you should get it fixed by a professional auto shop as soon as possible before it causes serious engine damage.