It’s surprising how many hidden costs quietly drain profits in manufacturing. They don’t show up on a single invoice, but they build up fast. Across Alabama industries, CNC machining is changing that story—cutting out waste and restoring control where manual processes once ruled.

Cost of Excess Material Waste

Material waste doesn’t always look like a problem until you track it closely. Manual cutting and shaping can lead to scrap rates that are quietly shaving down margins. Whether it’s aluminum, stainless steel, or high-density plastic, overcutting, mismeasuring, and unoptimized cuts result in piles of expensive leftovers. These costs sneak past most budgets because they’re often written off as routine loss.

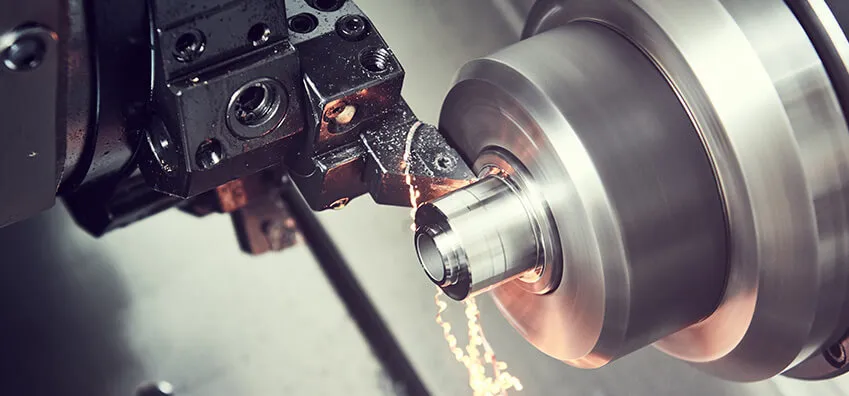

Switching to CNC machining in Alabama means letting precision take the wheel. Every cut, drill, or carve is digitally calculated to use just what’s needed—no more, no less. A robotics engineering company in Alabama running a CNC plasma cutter can design layouts that maximize each material sheet down to the millimeter. That control saves thousands in materials annually, especially for shops working with high-cost alloys or specialty composites.

Expense from Frequent Manual Errors

Mistakes on the shop floor can go far beyond surface-level frustration. Misaligned holes, off-center cuts, or incorrect tolerances often mean starting over—or worse, delivering flawed parts to clients. In industries like aerospace or defense manufacturing, even tiny missteps can lead to major losses.

CNC machining dramatically reduces that risk. Once a program is created and tested, it runs with reliable consistency across hundreds or even thousands of units. A robotics engineering company in Alabama using CNC-controlled systems sees a sharp drop in rework and returns. Operators shift their focus from fixing errors to optimizing outputs, which raises both quality and confidence on the production line.

Unexpected Downtime Costs

Downtime can hit at the worst times—like right in the middle of a high-volume order. Manual machines wear out, breakdowns take longer to diagnose, and it often takes hours just to resume production. These gaps aren’t always planned, but they sure cost like it.

CNC machining systems are built with diagnostic tools that keep downtime in check. With real-time monitoring, operators catch issues before they become shutdowns. A CNC plasma cutter setup, for example, allows scheduled maintenance alerts and faster part swaps. That means Alabama industries keep lines moving and avoid the spiraling costs of unplanned halts. What used to be hours lost is now minutes recovered.

Extra Labor Expenses from Manual Rework

Hand-finishing parts, recutting incorrect shapes, or repeating rejected batches stacks up fast in labor hours. Manual rework isn’t just about fixing something—it takes away time from new production and puts stress on deadlines. These labor spikes often require overtime, weekend hours, or extra shifts, adding strain to payroll and delivery times.

CNC machining in Alabama simplifies this drastically. Once a program is running, operators can manage multiple machines at once without sacrificing precision. With a properly calibrated CNC plasma cutter or mill, repeatable quality becomes the standard. That means fewer touch-ups, fewer reruns, and less reliance on after-the-fact corrections. The team’s time shifts from reactive to proactive, focusing on throughput instead of damage control.

Additional Tool Replacement Costs

Manual operations often rely heavily on operator feedback to monitor tool wear. That can lead to tools being overused, snapped, or replaced too soon—either way, it’s money down the drain. Misjudging tool health can even cause surface damage to parts, which introduces another layer of hidden cost.

In CNC machining systems, tool life is tracked with precise counters and analytics. Machines can auto-adjust for wear or signal replacements right when they’re needed. Whether cutting with a plasma cutter or high-speed end mill, the system takes the guesswork out of maintenance. This reduces unexpected tool purchases and keeps parts consistent in quality, no matter how long the run is.

Inventory Holding Expenses

Carrying large amounts of inventory may feel like a safety net, but it costs money to store, manage, and protect unused parts. Manual shops often overproduce just to account for breakage, rework, or demand uncertainty. That excess clutters shelves and ties up capital that could be used elsewhere.

CNC machining allows tighter production planning and just-in-time manufacturing. With fast setup changes and repeatable quality, businesses can produce only what they need—when they need it. A robotics engineering company in Alabama using CNC systems can scale production based on real demand without sitting on excess. This frees up space, reduces waste, and improves cash flow.

Quality Control Inspection Overruns

Manual processes often require extensive inspection to catch irregularities. That can mean more man-hours in quality control, slower batch releases, and longer turnaround times for clients. These costs multiply when audits or external reviews are involved.

With CNC machining in Alabama, consistency is built into the process. CNC plasma cutters and mills operate on exact programming, minimizing the variance between parts. Inspection becomes about verification, not salvage. By reducing the need for constant checks, teams gain time, clients receive better products, and costs drop across the board.